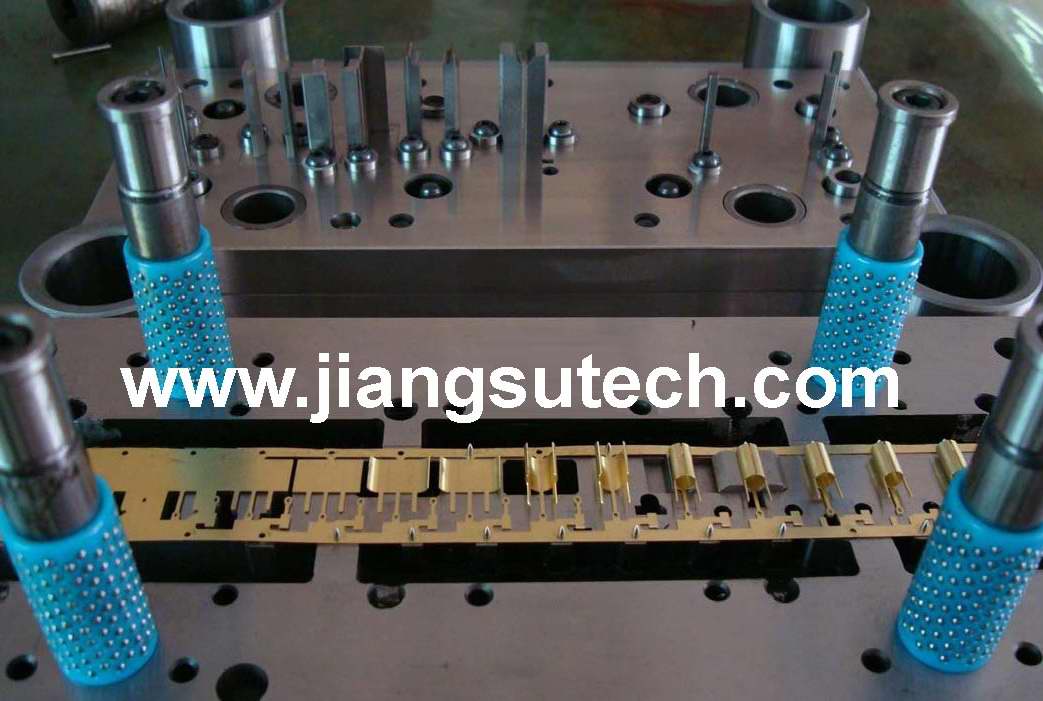

progressive die stamping

Progressive die presses stamp metal using a forming method that can encompass bending, cutting, punching and several other ways of modifying coil sheet steel. The automatic feeding system pushes a strip of metal (as it unrolls from a coil) through all of the stations of a progressive stamping die.

Each station performs one or more operations until a finished part is made. The final station is a cutoff operation, which separates the finished part from the carrying web. The carrying web, along with metal that is punched away in previous operations, is treated as scrap.

The progressive stamping die is placed into a mechanical or servo stamping press. As the press cycles, the top die moves up with the platen, which allows the material to feed through the die. When the press platen moves down, the die closes and performs the stamping operation. With each stroke/cycle of the press, one or more completed parts are cut off and removed from the die.

Since additional work is done in each “station” of the die, it is important that the strip be advanced very precisely so that it aligns within a few thousandths of an inch as it moves from station to station. Bullet shaped or conical “pilots” enter previously pierced round holes in the strip to assure this alignment since the feeding mechanism usually cannot provide the necessary precision in feed length.

Progressive die presses come in many sizes from renowned press manufacturers such as Aida, Blow, Bruderer, Chin Fong, Danley, Komatsu, Minster, Schuler, Mueller Weingarten, Seyi, Stamtec, Sutherland, and Verson.

Jiangsu Tech offers progressive die stampings utilizing state of the art press technology to maximize efficiency. We match each stamping component with the ideal manufacturing technology to give our customers the highest quality stamping parts at the lowest cost.