Ceramic Injection Molding (CIM) is ideal for near net-shape, high-volume production of complex, tight-tolerance ceramic components. Ceramic Injection Molding offers significant advantages over conventional forming methods:

Advantages:

• Cost-effective technique for complex designs

• Ability to produce net or near-net shape parts

• Very tight tolerance control

• Low-cost, high-volume manufacturing runs

Complex ceramic parts can be manufactured easily and reliably

high-quality ceramic injection molding opening up new possibilities for making complex components with economic and technical benefits:

• High degree of automation

• Wide range of shapes

• Near-net-shape manufacturing

• Good mechanical properties

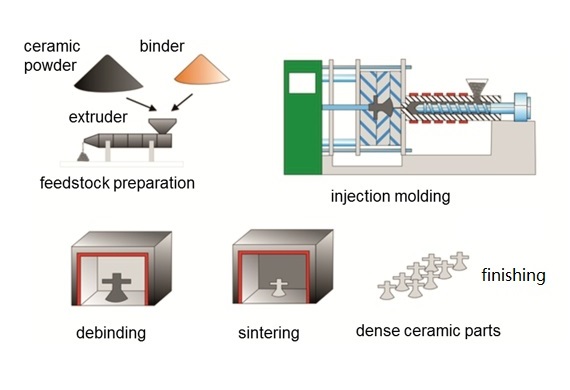

Ceramic Injection Molding Process

Material Preparation – Our application engineer help you choose from variety of advanced technical ceramics.

Molding – State-of-the-art injection molding machines heat feedstock to a flowable state and pressure inject it into a steel mold. The part then is cooled until solid and ejected from the mold

Debinding – Some materials may require either thermal or chemical bath debinding prior to the sintering process.

Sintering – In kilns capable of exceeding 1700° C, ceramics are sintered to full density, removing any remaining binders or organics.

Finishing Operations – If needed, operations such as ceramic machining, grinding, Lapping and Polishing Services are available to meet customer specifications.

Materail:

Alumina(Al2O3)96%-99%

Zirconia (ZrO2)

Applications:

Automotive industry

Consumer goods

Machine construction

Communication / electronics

Medical technology

Ceramic Injection Molding (CIM) Parts