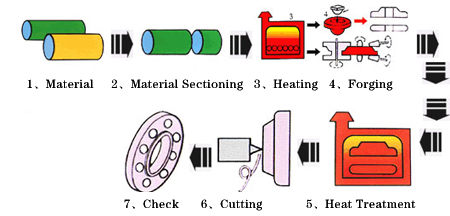

Forging Process

Forging is the operation where the metal is heated and then a force is applied to manipulates the metal in such a way that the required final shape is obtained. This is the oldest of the metal working processes known to mankind since the copper age.

Forging is generally a hot working operation though cold forging is used sometimes.

Forging dates back to ancient times and was associated with the village blacksmith. Virtually all ductile metals may be forged by first preheating the work piece to a forging temperature. The work piece can be a billet, a wrought bar, a cast or sintered ingot etc. The forging process can then be completed by hammering the work piece to the desired shape.

Forging has a marked beneficial effect on the metals being shaped. Their toughness and strength are improved because the process results in a beneficial orientation of the metal grain structure. The repeated hot working causes the metal to become more dense and the grain “flow lines” to follow the contour of the final component.

Open Die Forging

Open die (smith forgings) are made by using hammers or presses in conjunction with blacksmith tools or flat type dies. There is little lateral confinement of the work piece. The desired shape is obtained by manipulating the workpiece between blows.

This process employs low cost tooling, is relatively simple, but has less control in determining grain flow, mechanical properties and dimensions than other forging methods. This process can only be carried out by skilled operators.

Closed Die Forging

This process is based on hammering the work pieces into into the desired shape by means of closing dies. The hammering or pressing is performed, respectively, by a mechanical or hydraulic press. Small and medium sized forgings are generally made in presses ranging in capacity from 500 to 10000 Te.

Closed die forgings have good dimensional accuracy, with improved mechanical properties compared to open die forgings. The process has good reproducibility and rapid production rates are possible. The initial cost of tooling is very high.

Upset Forging

This process uses barstock which is heated at the end which is being forged. The bar is gripped in the fixed half of a die so that the length of material being forged projects. The forging blow is delivered by a moving die. Simpled shapes are produced in a single stage but more complicated shapes require multiple stages.

Rolling

Rolling is the most important metal working process and can be performed on either hot or cold metal. Material is passed between cast of forged steel rolls which compress it and move it forward. Rolling is a economical method of deformation if metal is required in long lengths of uniform cross section. Normal rolling achieves thickness reduction of about 2:1.