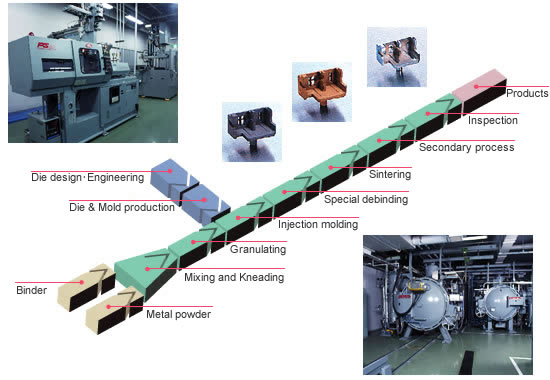

As the pressure to produce smaller and more complex parts faster and more economically increases, manufacturing using MIM (metal injection molding) and AM (additive manufacturing) processes such as 3D printing is gaining widespread acceptance. Manufacturing options like MIM and AM have opened up design possibilities that are almost limitless, allowing designers to create parts that would otherwise be impossible to make using other manufacturing methods. For example, in the past, design compromises had to be made for parts that were […]